Description

– ideal for numbering glued SD sets

– complete with feeder suction and blowing air in basic equipment

– 1 Paint roller

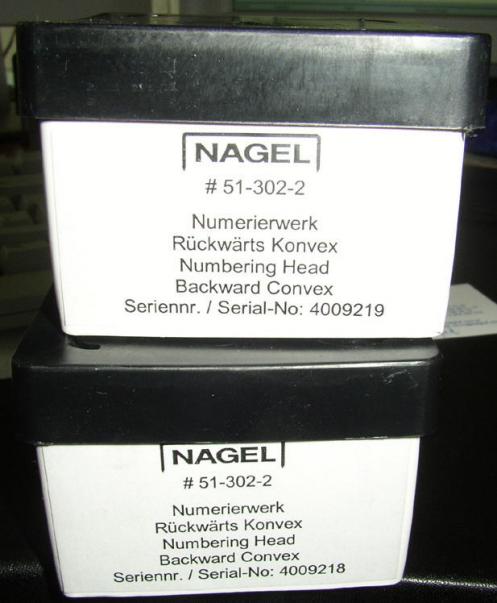

– 1 piece numbering shaft

– 2 pieces seat rings

– 2 rotary numbering units

With its suction feeder, the Numnak perforating/numbering machine processes a wide range of papers. The easy accessibility of the parts makes setup and cleaning possible in just a few moments. With many extras, the Numnak enables increased flexibility in the assignment and utilization of your presses.

– rotary numbering as on a printing press (e.g. GTO – Heidelberg)

– powerful suction and blowing air feeder processes a wide range of papers

– carbon copies can also be numbered, the Numnak prints the numbers – its heavy construction guarantees high accuracy

– the Numnak can be equipped with degree and transverse enumerators

– Positioning of the number in any place – also on the edge of the sheet or on the perforation

– Production is considerably faster and quieter than with numbering machines based on the stamp principle.

– Ink is applied by microporous ink form roller – unlike printing presses, 2 colors are possible at the same time

– simultaneous peforating like on a folding machine – also slitting and creasing tools possible

– processes formats up to 460mm width

max. Performance (cycles per hour):

1 – 4 plants = 9,000

5 – 6 works = 5,000

7 – 8 plants = 4,000

max. Number of numbering units: 8

SD sets: 7 sheets maximum, 45 g/m² minimum

max. Paper size: 460 x 460 mm

min. Paper size: 210 x 125 mm ( length x width)

Connection: 230 V / 50 HzoMasses: L 1340 x W 780 x H 1050 mm

Weight: 162 kg