Description

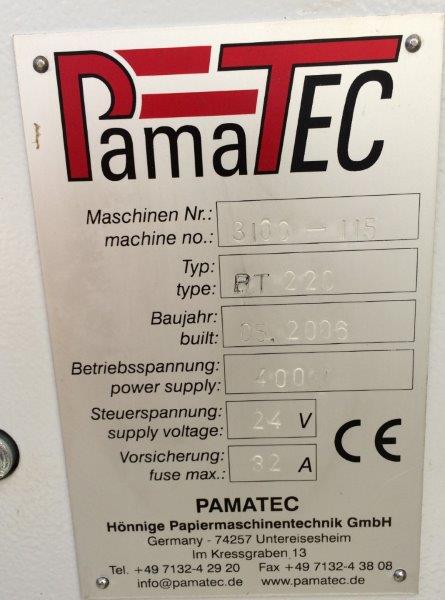

fully automatic inline bridge punching machine PamaTec OEM Heidelberg PT-220

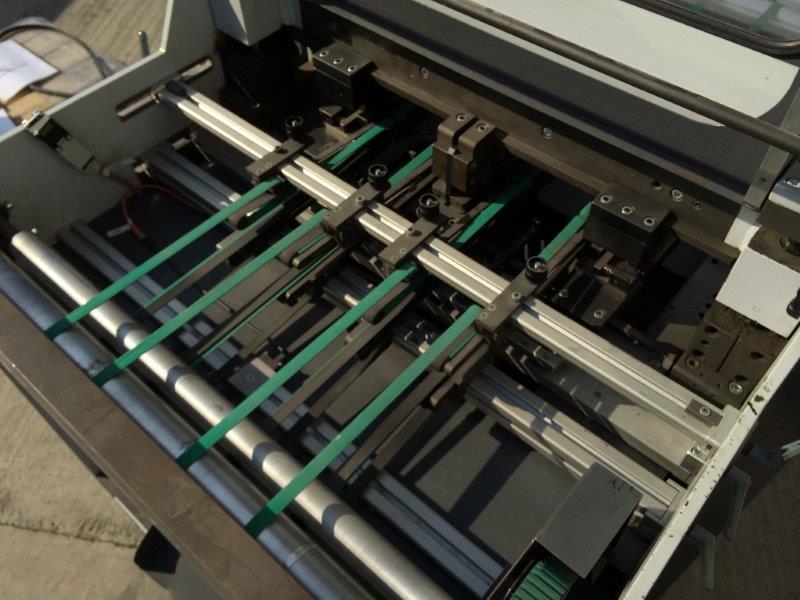

configured for longitudinal cutting, steel rule cutting, line tools and cross cutting

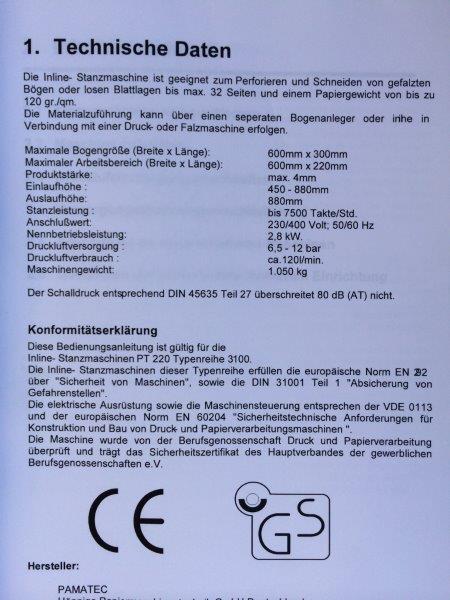

Punches folded layers and single sheets behind the folding machine or saddle stitcher.

Depending on the product length and thickness, the maximum cycle speed is 7,500 copies per hour.

The maximum die-cutting format is designed for 600 x 220 millimeters.

A wide range of finishing options can be implemented: Tear-off or corner perforation, Wire-O punching and filing holes.

Parting, register and three-side trimming are possible, as are steel rule cuts for individual die cutting,

the tools needed for this are not included !!!

The product thicknesses that can be processed are four millimeters for cutting,

for perforating at three millimeters and for steel rule cutting at two millimeters.

Sheets are transferred directly from the folding machine or saddlestitcher with a height-adjustable belt feeder.

A pneumatic alignment system ensures accurate positioning of the sheets in the die cutter

and thus for high punching accuracy.

Inlet width 70 cm

Working width 60 cm

Equipment

Belt conveyor for 2 panels with 4 conveyor belts 15 mm wide,

1 receptacle for longitudinal cutting,

Cutout tool (width 6mm optional 8-10-12-15mm are also available,

2 receptacles for line tools punching pattern Euro perforation

Recording strip steel cutting, pre-direction,

Transfer outlet,

Central lubrication,

TF interface.

Explanation cutting types:

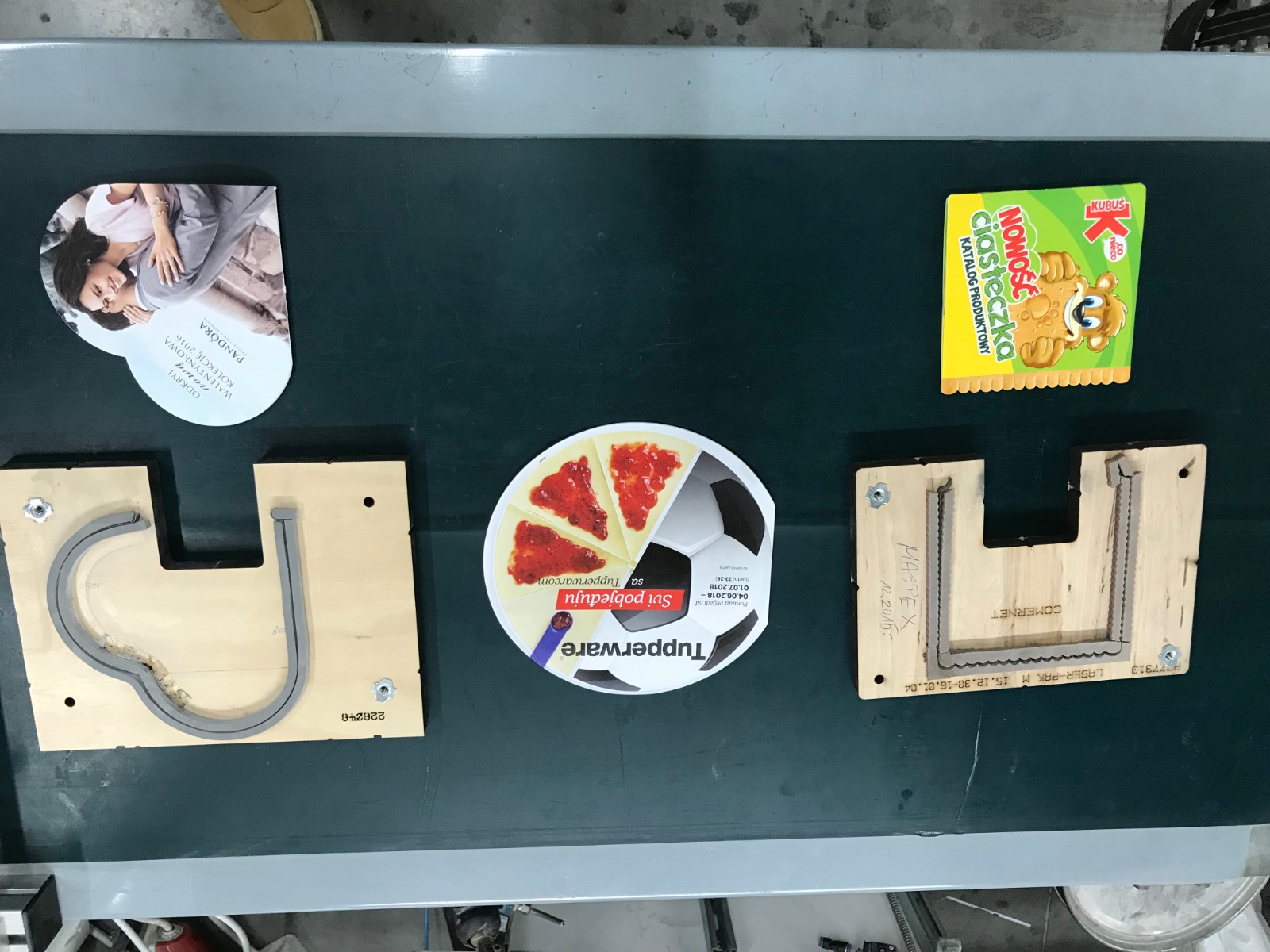

Steel strip cutting: any shape punching up to 2 mm thickness

Longitudinal cut: head and foot trim, separating cut, strip cutout

Cross section: cutting work at right angles to the direction of paper travel, e.g. front trim

Line perforation: e.g. corner perforation, Wire-O or filing perforation

Central lubrication to supply all bearing points with grease for the drive.

This should be operated at least once a day.

The progressive distributor ensures uniform greasing.