Description

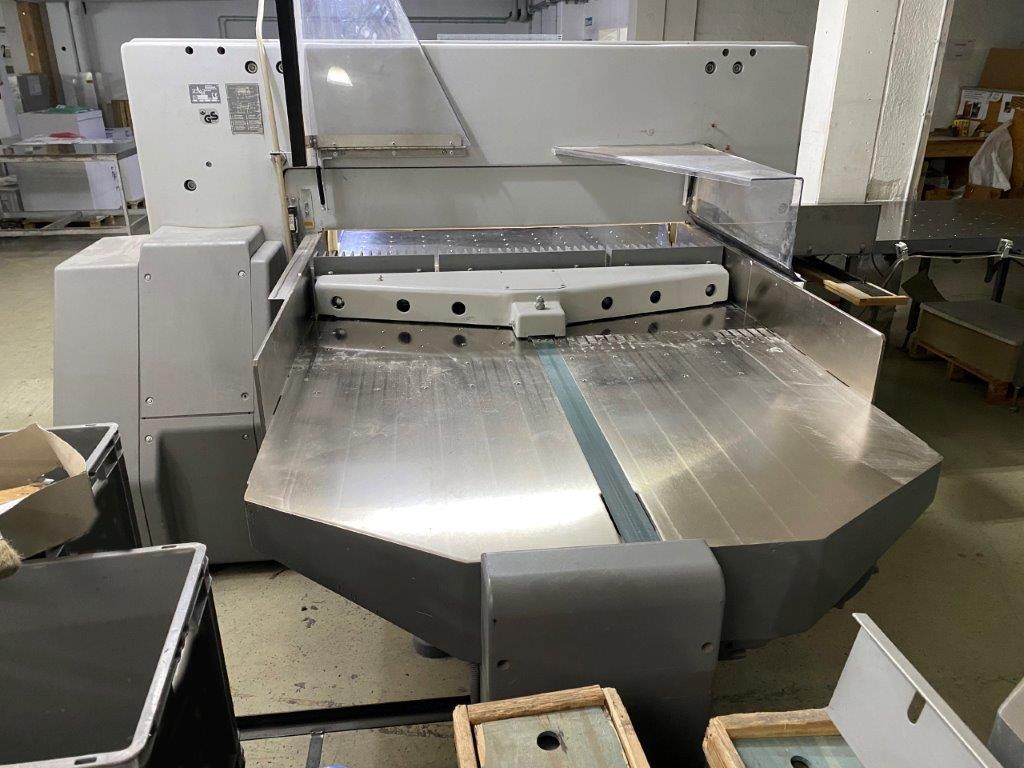

Large sized cutting system Polar 137 XT-AT with stacking lifter, automatic vibrator and scale

set up in 2005

The workflow:

The cutting material is brought to the left side with a Beladelift to an optimal working height,

placed by the operator in the vibrator, shaken there

and then transported via a transfer table element on the front table of the high-speed cutter.

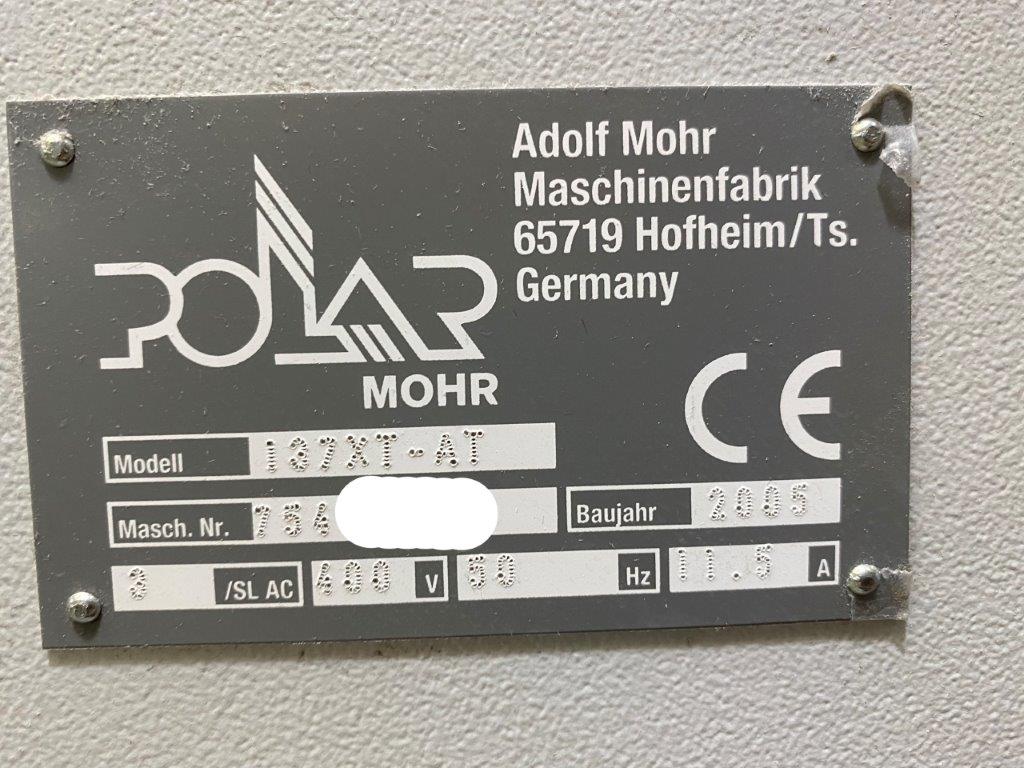

Cutting machine Polar 137 XT-AT with Compucut P-net CIP 3 Connecting

built 2005

Equipment

– Autotrim – waste removal (bay on the table to place a container below or for a connection to a suction, needs to be connected to an existing pressure connection)

– nickel-plated air tables

– 2 knives

Cutting length 1370

mm

insertion depth 1450 mm insertion height max. 165 mm

Pressing pressure 550-5500 daN

front table depth 730 mm

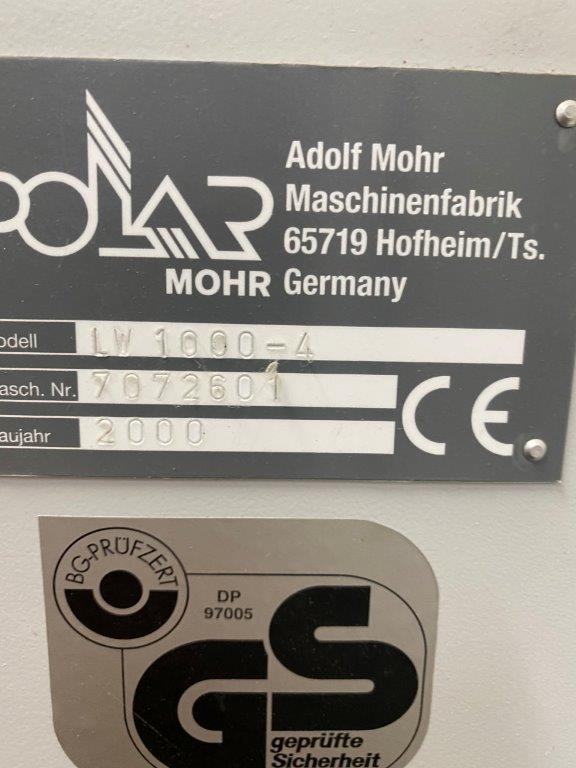

Polar stack lift LW 1000-4

built 2000

Platform 80x126mm

By automatically lifting the material to be cut, the operator can load

the material into the automatic vibrator or directly into

the cutting machine at an ergonomically favorable working height .

The stack lift can also be used for stacking of cutting material and has an adjustable stacking aid.

Stacking lifts do not have to be anchored in the ground and can therefore be easily converted.

They are equipped with infinitely adjustable retro-reflective sensors for automatic lifting or lowering.

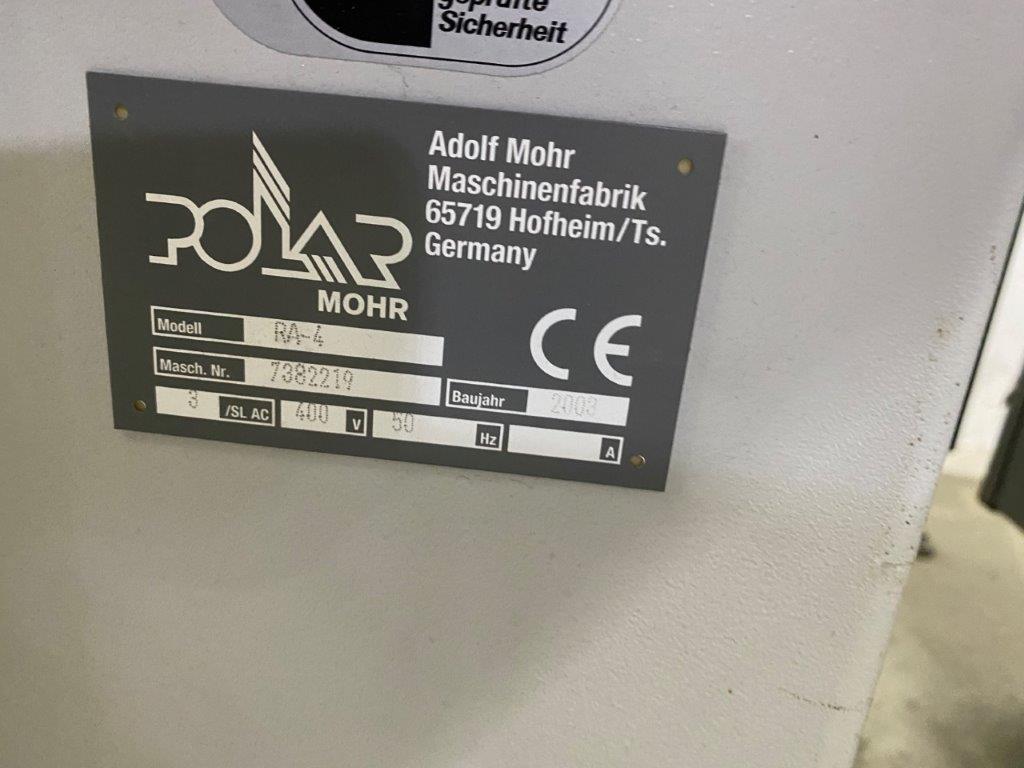

Automatic vibrating machine RA-4 with air

built 2003

wiping roller After completion of the shaking process the air is pressed out of the cutting position.

They can be spread out 1 or 2 times, whereby the pressing pressure of the first spreading process is adjustable and with an inclined table also “spread out in between”

Table size 900x1150mm stainless steel-plated Layer height

min. 30 mm

layer height man. 165 mm

table height 860 – 950 mm

Compressed air requirement at 6 – 8 bar approx. 2L / min

sheet scale – Polar Mohr counting scale for platform

for creating precise cutting positions

08_Produktblatt_POLAR_TRE_dt_03.2012

optional

Polar Transomat 1 ER 130-4 for unloading

built 2002 – overhauled

Places split and undivided layers automatically on pallets while rescoring them at the same time.

This reduces production costs by 25 to 70 percent, depending on the cutting program.

Thanks to the patented, movable pallet tip, the POLAR Transomat achieves particularly high edge accuracy.

Advantages:

Increase of productivity: Stacking at the same time as cutting

– Improvement of quality: Particularly edge-exact stacks can be processed directly and faster.

included option

Automatic format setting – Simplified operation, as the format setting is fully automatic via sensor.

complete protection housing