Description

for precise adhesive application in high-speed machines

can control 8 channels

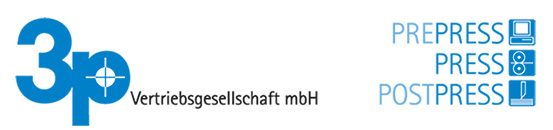

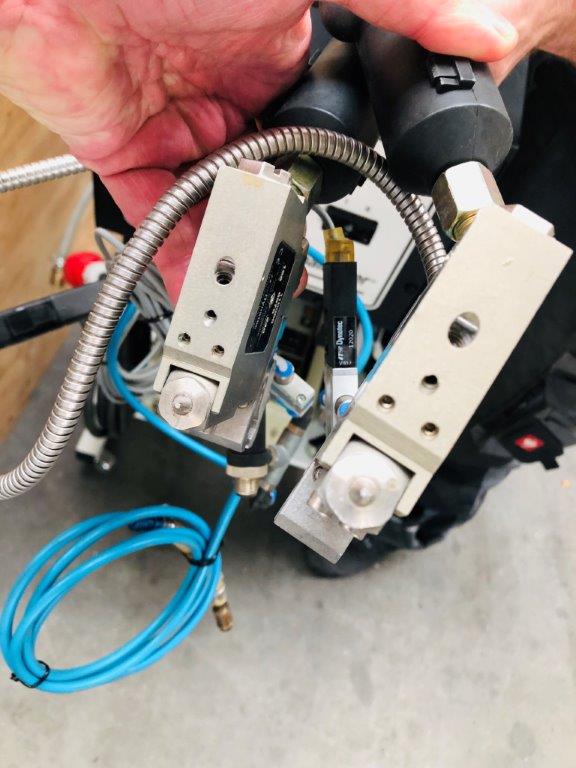

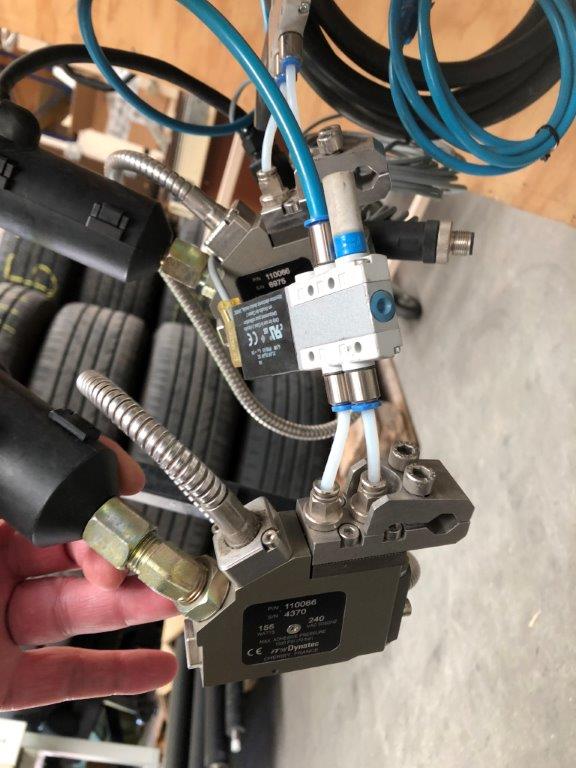

and up to max. Supply 4 glue application valves

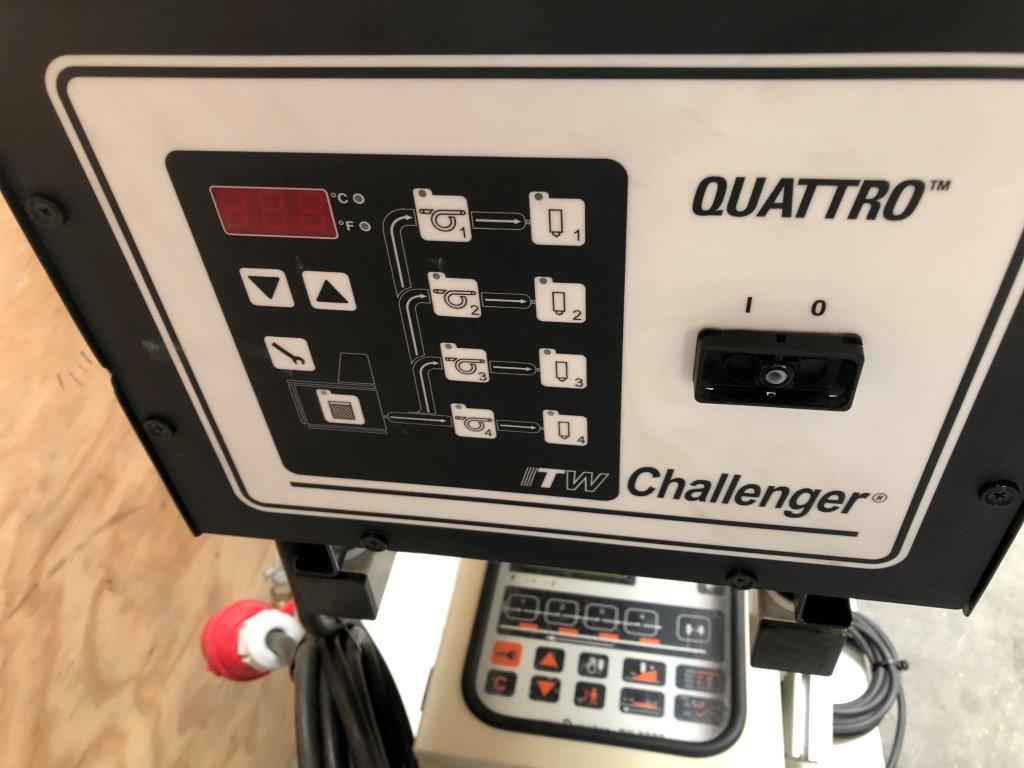

- 1 Dynatec Quattro Challenger

- Tank filling capacity 8.5 kg

- Operating temperature 38 to 218 °C

- Melt rate / hour 9 kg/h

- Pumping rate 871 g/min

- Compression ratios piston pump 14:1

- Hose outlets 4

- Temperature stability ± 1 °C

- Maximum hydraulic pressure in operation 7 bar – piston pump

- Electrical supply 200 – 240 V

- 1-3 phases 50/60 Hz

- Electrical supply 380 V

- 3 phases wye 50/60 Hz

- Viscosity in operation 500 to 30,000 cps

The Dynatec Advantage ITW Challenger® Quattro™ Melter

-Flexible temperature settings for improved adhesive properties

-Very reliable piston pump

-Teflon-coated tank allows filling with all common hot melt granulate forms such as pellets, balls as well as blocks

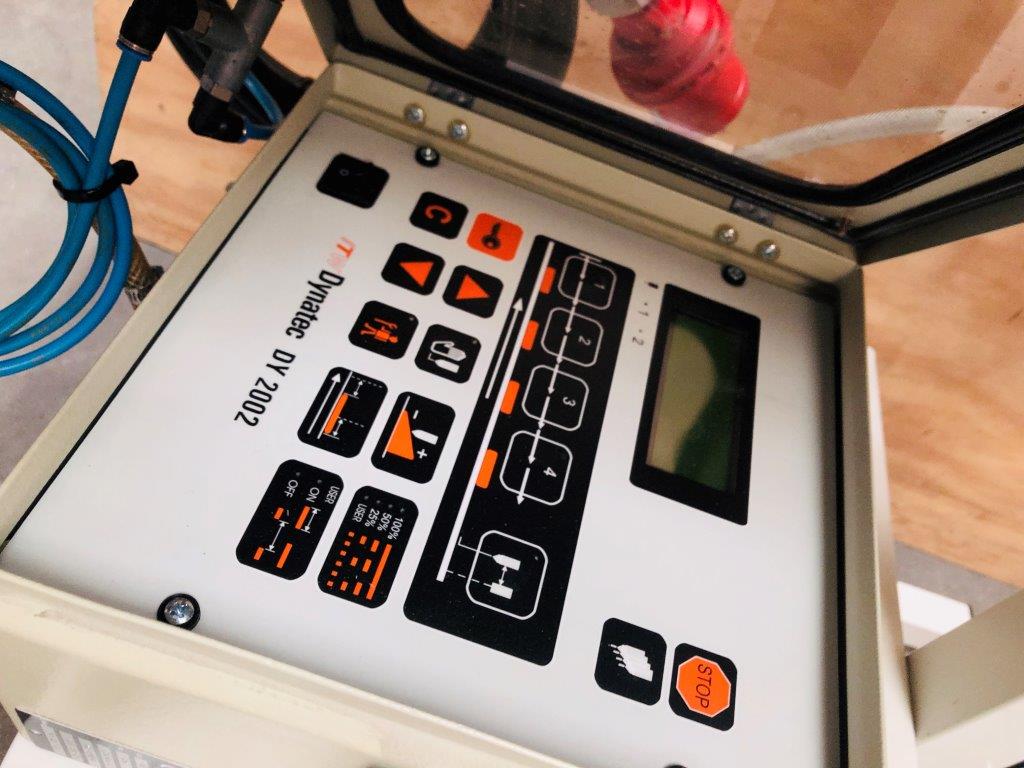

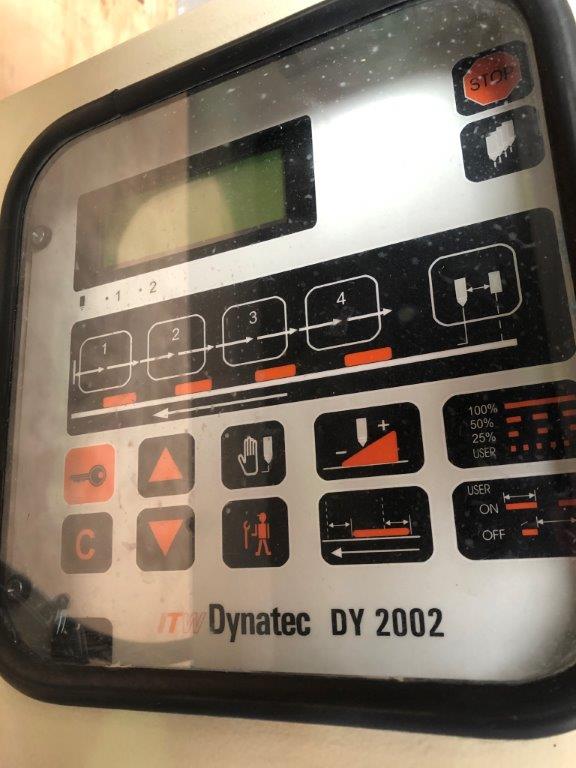

1 Dy 2002 Control unit for 8 channels

2 heating lines approx. 1.80 and two application nozzles on trolleys