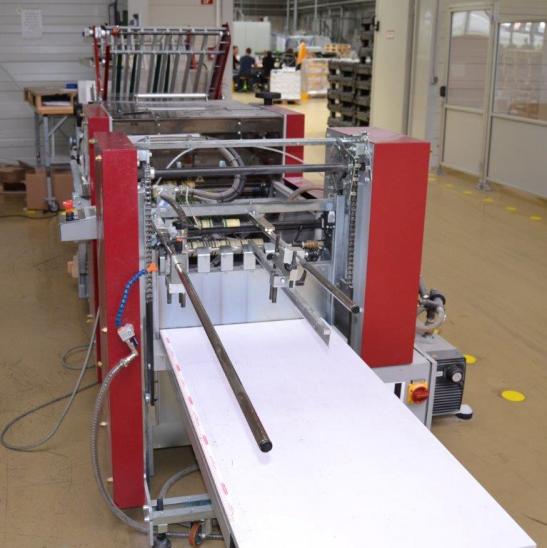

Description

with 2 creasing tools and window folding pocket

Creasing, gluing, folding

The sheet is fed to an inclined belt alignment via a flat pile feeder and taken over by infeed rollers. The beginning of the sheet is detected by a light barrier. Positive and negative creasing or cross perforation are carried out in one pass via the masses entered at the control. To fix flaps to brochure covers, glue can now be applied using a hotmelt nozzle (option). The sheet is then transferred to a special buckle plate folding unit and folded at the creased areas. The product is dispensed into a shingle belt display.

Material thickness 170 to 500 g/m²

Sheet width 150 to 520 mm

Sheet length 200 to 1,200 mm

Creasing distances are adjustable in 0.1 mm steps

Effective output in A-4 format with one crease 12,500 sheets/hour